In today’s competitive manufacturing landscape, the demand for precision, efficiency, and rapid production is higher than ever. A CNC Precision Machine Shop stands at the forefront of this industrial evolution, offering significant advantages that can transform traditional manufacturing processes. Understanding how these high-tech facilities operate and the benefits they provide is crucial for businesses looking to enhance their production capabilities.

Unveiling the Potential of CNC Machining

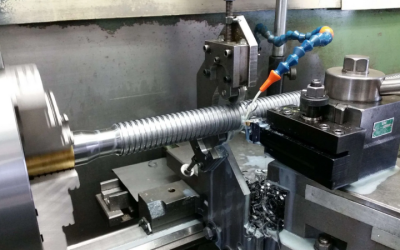

CNC (Computer Numerical Control) machining is a process used in manufacturing that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers, and grinders. The CNC in CNC Machining stands for Computer Numerical Control, which means the computer converts the design produced by Computer Aided Design software (CAD), into numbers. The numbers can be considered as the coordinates of a graph and they control the movement of the cutter. In this way, the computer controls the cutting and shaping of the material.

Precision and Consistency

One of the primary benefits of utilizing a CNC precision machine shop is the incredible accuracy and consistency they offer. CNC machines operate with an astonishing level of precision, often within 0.0001 inches. This precision is critical in industries where a minute discrepancy can lead to a significant failure in the end product.

- Reduced Human Error: Automation minimizes the chances of human error, ensuring that every part is produced with uniformity and exactness.

- Repeatability: Once a design is input into the CNC machine, it can produce hundreds or thousands of parts that are exact replicas of each other.

Speed and Efficiency

CNC machines are not only accurate but also significantly faster than manual machining. Once the design parameters and specifications have been programmed, CNC machines can operate almost continuously with minimal supervision.

- Faster Turnaround Times: This capability allows for quicker production cycles, helping businesses respond rapidly to market demands.

- Less Wastage: Precision machining reduces material wastage, which is economically beneficial and better for the environment.

Flexibility and Customization

CNC machining offers unparalleled flexibility in manufacturing. With the right programming, a CNC machine can produce any part that fits within its working envelope.

- Complex Designs: CNC machines can create complex shapes that would be almost impossible to achieve with manual machining.

- Customization at No Extra Cost: Switching between configurations doesn’t require additional tools or setups, which lowers the production costs.

Cost-Effectiveness

Investing in CNC technology might seem expensive initially, but it pays off in the long run. The efficiency and speed of CNC machines mean they can produce more parts per hour than manual machines, which translates to a lower cost per unit.

- Reduced Labor Costs: CNC machines require fewer personnel for operation, reducing labor costs.

- Lower Error Rates: The high accuracy reduces the cost associated with defective parts and rework.

The integration of a CNC precision machine shop into your manufacturing process is not just an upgrade; it’s a revolutionary change that enhances every aspect of production. From unbeatable precision and consistency to impressive speed and flexibility, the advantages are clear. By reducing waste, speeding up production, and cutting costs, CNC machining helps businesses stay competitive in a demanding market. As technology continues to advance, the capabilities of CNC machining will only grow, further solidifying its role as a cornerstone of modern manufacturing.