Aligning machines to work properly isn’t as time consuming as it used to be. Not too long ago, companies concerned about obtaining a profit would have had to close down to have their machines and tools calibrated and aligned. Today, with the use of lasers, the alignment is quicker, more efficient, and the company can stay open and running when the machines are aligned. This is a big boost to the company when no downtime is involved, and profits can remain stable. When tool calibration is needed because of constant use, or machines have to be aligned due to vibrations, knowing which company to call for help is extremely important.

Companies that provide the perfection of Laser Precision to constantly used machines are located nearby. These are companies with technicians who’ve been taught their job by their company, and have also undergone on the job training. They do the very best job possible when utilizing the Machine Laser in Austin. Fortunately, companies no longer have to shut down or wait for the right moment to calibrate their tools and machinery. These companies use Hamar Laser Alignment Applications and the Renishaw Laser that won’t interfere with the normal workday of the company.

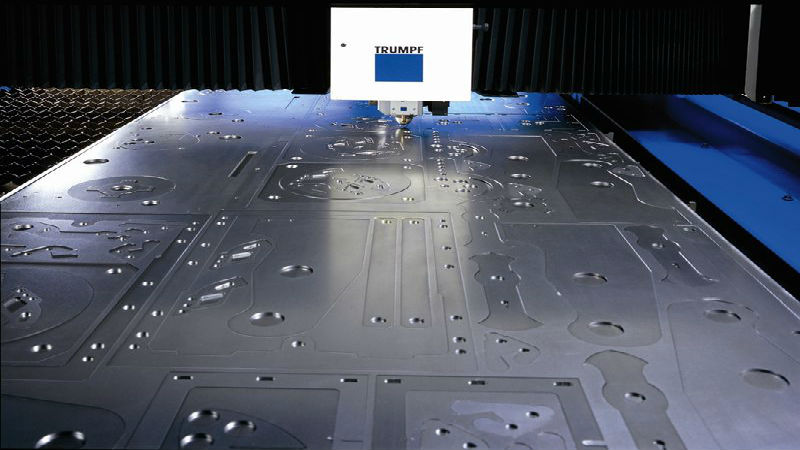

These precision lasers will add extra life to machinery, which saves a company’s money by calibrating tools and machinery much more quickly and efficiently. If your company doesn’t want to shut down during the tool and machinery calibration process, call a local company that specializes in Machine Laser in Austin. Professionals will ensure your equipment runs at top speed, with the highest precision and performance. This is how companies stay ahead of the pack and keep making high profits. When every machine is working at full capacity, everyone is happy.

The laser applications offer machine geometry, spindle alignment, bore, and coupling. Roll alignment for printing presses, paper and process mills is also available. Companies using laser alignment do jobs that used to take three days, in one day. Machines that work more efficiently also last longer. Because they last longer, it increases the profit margin of companies that normally had to close down in order to have their machines and tools calibrated.